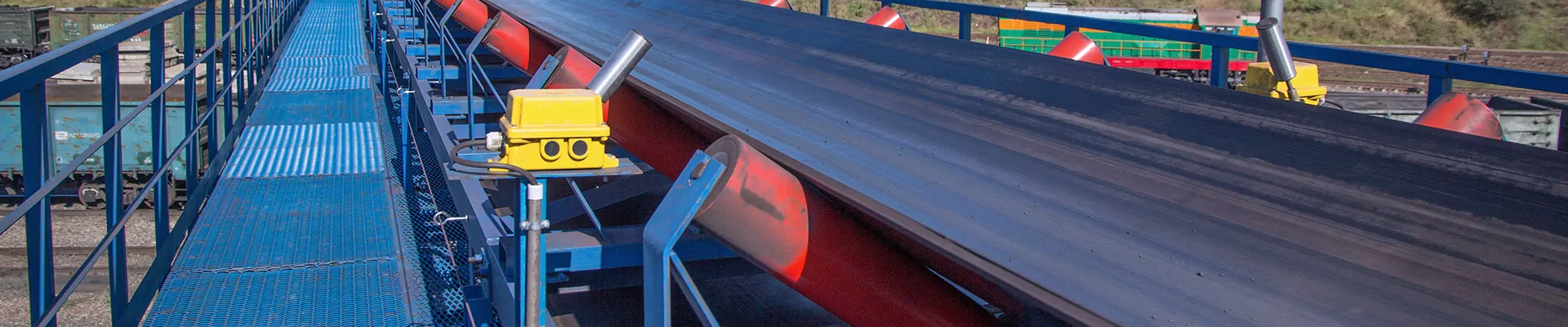

The Drive Pulley (also known as the Head Pulley) is the primary powered pulley in a conveyor system, responsible for transmitting the mechanical force from the motor and gearbox to the conveyor belt. It is the key component that initiates and sustains belt movement, enabling the transportation of bulk materials.

![]()

![]()

![]()

Key Components & Construction:

Drum / Shell: The main cylindrical body, typically fabricated from robust steel. Its diameter and face width are critical design parameters based on system horsepower and belt tension.

Shaft: A high-strength, machined steel shaft that runs through the center of the drum, supported by bearings. It transmits the torque from the drive assembly.

Lagging: A protective, high-friction layer vulcanized or bonded to the drum's outer surface.

Purpose: Increases the coefficient of friction between the pulley and the belt, preventing slippage and ensuring efficient power transfer.

Types: Common types include Plain Rubber Lagging, Diamond/Grooved Rubber Lagging (for better cleaning and grip in dirty conditions), and Ceramic Lagging (embedded ceramic tiles for extreme-friction applications in wet or muddy environments).

End Disks & Hubs: Connect the drum to the shaft, ensuring structural integrity and torque transmission.

Bearings: Mounted in robust bearing assemblies (often pillow block bearings), they allow the shaft and pulley to rotate smoothly under heavy loads.

Primary Functions:

Power Transmission: Converts rotational power from the drive unit into linear motion of the belt.

Traction Control: Through its lagging, it maintains sufficient grip on the belt, especially under start-up, high-load, or inclined conveying conditions.

Belt Tracking (Crowned Pulleys): Many drive pulleys are slightly crowned (center diameter larger than ends) to help centralize and guide (track) the belt, preventing run-off.

Types & Configurations:

Single Drive Pulley: The most common setup, where one pulley is powered.

Tandem Drive Pulley: Features two pulleys on the same shaft, effectively doubling the wrap angle and traction for high-horsepower applications.

Crowned vs. Flat Face: Crowned pulleys aid tracking; flat-faced pulleys are often used with timing belts or in specific system designs.

Bare vs. Lagged: Almost all drive pulleys are lagged. Bare steel pulleys are only used in very low-power or non-critical applications.

Selection & Design Considerations:

System Horsepower & Torque: Determines the required shaft diameter, drum strength, and overall pulley size.

Belt Tension: Dictates the pulley's mechanical design and bearing selection.

Belt Speed & Width: Determines the pulley's diameter and face width.

Wrap Angle: The amount of belt contact around the pulley (typically 180° to 240°). A larger wrap angle increases traction. Snub pulleys are sometimes used to increase this wrap.

Environmental Conditions: Influences the choice of lagging type (e.g., ceramic for wet conditions) and corrosion protection (painting, coating).

Importance in System Health:

A properly specified and maintained drive pulley is critical for:

System Efficiency: Prevents energy loss due to belt slippage.

Belt Life: Reduces wear caused by slippage and mis-tracking.

Operational Reliability: A failed drive pulley brings the entire conveyor system to a halt.

Safety: Proper guarding and secure lagging are essential to prevent catastrophic accidents.